Tear Resistance Explosive Cartridges Application Cross Laminated

Film

Product Description:

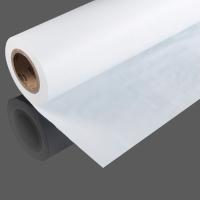

What is cross laminated strength film?

It is a high-strength multi-layer composite film,It is made of HDPE

as the base material,

adding plasticizer, plasticizer, stabilizer, antioxidant, UV

absorber, toughener and other

additives through multi-layer co-extrusion blow molding into

embryos, and then by multiple

pull Stretching, then rotary cutting into a film substrate with a

horizontal and vertical distribution

of 45 °, and finally through cross-compositing. Due to its

cross-stacking structure is different

from ordinary single-layer or multi-layer film, it has the thermal

stability, dimensional stability,

two-way tear resistance, two-way uniform tension and high

elongation which are not available

in traditional films.

Why cross laminated strength film?

When conditions demand high-performance packaging, Cross Laminated

Strength Film

is your solution. Fungicides, pesticides, toilet bowl drop-ins, and

pool chemicals can be

packaged in confidence, with proven child-resistance, when you use

Cross Laminated

Strength Film. High-performance packages made with Cross Laminated

Strength Film

provide high burst strength, unbeatable tear-resistance, superior

moisture and chemical

resistance, as well as outstanding printability.

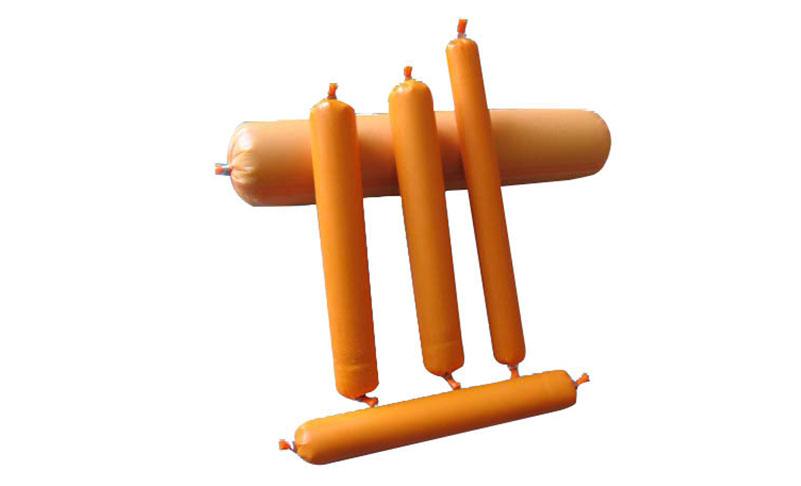

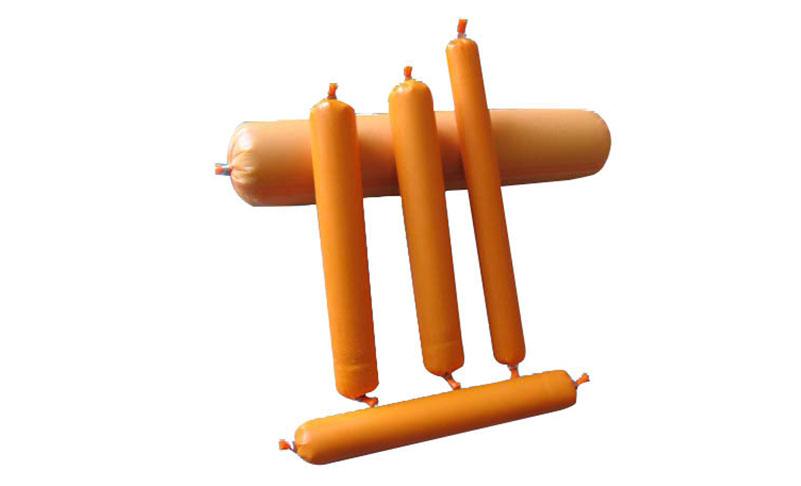

Cross laminated film is used in high impact resistant explosive

cartridges for form,

fill and seal (FFS) packaging of emulsion or water gel explosives.

Cross laminated film provides low elongation that assists in the

filling and production of emulsion

explosives at high fill temps without creating a baggy film on the

finished chub.

The finished chub remains rigid throughout the manufacturing and

transport process,

ensuring blast integrity on site. It also provides excellent

resistance to tear which protects the cartridge

from puncture during installation in a bore hole.

Because of Cross laminated film unparalleled strength, puncture,

tear and tear propagation resistance

in combination with high dimensional stability we are able to stand

up to the rigors of government and

military applications.

Advantages:

► Puncture Resistant

► High Thermal Stability: The ability to be used in any climate

because of cross laminated film's

ability to withstand temperatures ranging from -30°-80°C. Provides

a wide temperature filling range,

making cross laminated film the ideal material to pack explosive

gels and hot filled emulsions.

► Barrier against chemical migration

► Waterproof and Chemical Resistant: Barrier against water and

moisture. The closed tructure

(non porous, high barrier) of cross laminated film creates the

ideal material in which your

explosives are securely packed.

► High seal strength with polymer seams

► Minimal Elephant Footing: cross laminated film outperform other

films on site.

It drastically reduces chub or cartridge distortions when dropped

down the borehole.

Application:

Parameter:

| NO. | Item | Performance |

| | SDM-30 | SDM-60 |

| 1 | Tensile Property | Tensile Strength/Mpa ≥ | 30 | 50 |

| | MaxF/(N/50mm) ≥ | 200 | 300 |

| | Elongation as MaxF/% ≥ | 200 |

| | Elongation at break/% ≥ | 250 |

| 2 | Sample number of no broken tested by free-falling dart method ≥ | 8 |

| 3 | Tear Strength(Nail Shank)/N ≥ | 60 |

| 4 | Angle Tear Strength/N ≥ | 25 |

| 5 | Thermal Stability | 120 ℃,10min, No bulb, No deformation |

| 6 | Cryogenic Flexibility ℃ | -35℃, No fissure, No delamination |

| 7 | Thermal Ageing | Appearance | No bulb, No deformation |

| | Subsequent MaxF/% ≥ | 80 |

| | Elongation at MaxF/% ≥ | 200 |

| | Elongation at break/% ≥ | 200 |

| 8 | Artificial Weathering | Appearance | No bulb, No deformation |

| | Subsequent MaxF/% ≥ | 70 |

| | Elongation at MaxF/% ≥ | 180 |

| | Elongation at break/% ≥ | 180 |

Main Market:

FAQ:

Q1: Are you trading company or manufacturer ? A1: We are manufacturer.

Q2: Do you provide samples ? is it free or extra ? A2: Yes, we could offer A4 sample for free charge but if you need

in roll, we can offer 100-200m/roll for free, but shipping cost need you to

paid.

Q3: How long is your delivery time? A3: Depends on your quantity. Generally it is about 30 days for

20GP container.

Q4: How to pay for your goods? A4: By L/C, by T/T (30% deposit before production, 70% balance

before loading). |